-

Thickening Product For Ores In Iran

The Role Of Ore Properties In Thickening Process. Ferride geochemistry of swedish precambrian iron ores abstract: the role of ore properties in thickening process was studied in this research. the shaking table was used to prepare the sample for the tests. the tailings were continuously fed on the table by gravity to separate the tailings in three products as slime, middling and coarse .

Get Price -

: Reduction of Metals

· Reduction of Iron; Contributors; The ease with which a metal may be obtained from its ore varies considerably from one metal to another. Since the majority of ores are oxides or can be converted to oxides by roasting, the freeenergy change accompanying the decomposition of the oxide forms a convenient measure of how readily a metal may be obtained from its ore.

Get Price -

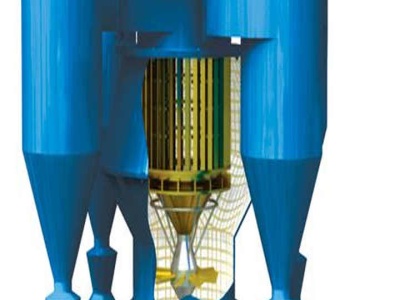

High rate thickener HRTHK

Thickeners are utilized in various solid/liquid separation processes in order to increase the density of a process stream. Feed solids concentration is the single most important variable affecting the sedimentation properties of given slurry. Highrate thickener. ANDRITZ process engineering will determine the optimum percentage of feed solids ...

Get Price -

How is steel made? Difference between BFBOF and EAF ...

· The key difference between the routes is the type of raw materials they consume. For the BFBOF route these are predominantly iron ore, coal, and recycled steel, while the EAF route produces steel using mainly recycled steel and electricity. Depending on the plant configuration and availability of recycled steel, other sources of metallic iron ...

Get Price -

different ores of iron

different ores of ironpakistan crusher stone crusher Gulin machine in iron ore processing plant different ores of iron. Gulin provide the different ores of . Read More; different ores of irongujaratgenomics. Types of Iron Ore Hematite vs. Magnetite Did you know that there are different types of iron ore Iron is most often found in hematite and ...

Get Price -

High Rate Thickeners

Description. The HighRate thickeners became popular in the mid 1980's and are relatively newcomers to the sedimentation line of equipment. As already discussed previously Thickeners are a major component in a plant layout and occupy large spaces which may be saved by introducing highrate machines. Furthermore, they are normally positioned far away from the center of the .

Get Price -

Thickener vs clarifier: what's the difference ...

A thickener, in contrast, is designed to do just that — thicken. While a part of this process by definition releases the liquid, the quality of the overflow is secondary.

Get Price -

Sinter strength evaluation using process parameters under ...

View 1 peer review of Sinter strength evaluation using process parameters under different conditions in iron ore sintering process on Publons Download Web of Science™ My Research Assistant : Bring the power of the Web of Science to your .

Get Price -

High Density Sludge (HDS) Process

The dissolution of soluble metal compounds from ore and waste rock as well as the presence of contaminants in industrial process water can result in metal contaminated effluent. These dissolved ions are commonly precipitated using a lime neutralization pr ocess, which produces a low density sludge that is difficult to thicken and filter.

Get Price -

Processing of Nickel Laterite Ores on the Rise

Image: Nickel Ore Dryer. Some novel processes may employ pelletizing at this stage of the process, where drying also facilitates pulverization of the ore in preparation of processing on a disc pelletizer.. Pelletizing may also be used as a means of reintroducing recycle to the process.

Get Price -

Blast furnace process

· Combustion process. The iron in the processed ores must be dissolved out by chemical processes. This requires an element that binds oxygen more strongly than iron. This is exactly what carbon can do as a reducing carbon is fed to the blast furnace in the form of coke (pyrolyzed coal) from the coking sufficiently high temperatures, the carbon can .

Get Price -

Thickener, Mining Thickener, Tailings Thickener

The thickener is one of the indispensable equipment of each largescale beneficiation plant, which is suitable for the dewatering treatment of concentrate and tailings in the beneficiation, with the continuous improvement of mineral processing requirements, the disadvantages of traditional thickeners are becoming more and more prominent, such as slow .

Get Price -

Beginners guide to thickeners

· Beginners guide to thickeners. Thickening is a process where a slurry or solidliquid mixture is separated to a dense slurry containing most of the solids and an overflow of essentially clear water (or liquor in leaching processes). The driving force for the separation is gravitational, where the differences in phase densities drive the ...

Get Price -

Characterisation of the Physical and Metallurgical ...

Preferred characteristics for iron ore lumps used for blast furnace (BF) and direct reduction (DR) processes and the characteristics of Muko iron ores. According to the obtained results, similar endothermal peaks of different values were observed between 365–632°C during heating of the ore samples Ug1–Ug5.

Get Price -

Thickening – Clarifiion – PHOENIX Process Equipment

Thickening Clarifiion. PHOENIX provides a range of water recycling, clarifiion, and thickening technology, commonly provided for process water reuse and the thickening / volume reduction of residual process solids. These technologies typically result in efficient water recovery and reduced disposal costs.

Get Price -

What Is Nickel Smelting? (with picture)

Alex Newth Nickel ore must melt until it becomes a product known as liquid matte, which is usually around 45 percent nickel. Nickel smelting is the process that nickel ore goes through to eventually remove impurities and leave just the nickel metal. While the ores can come from different stones and sources, they have two egories: lateritic, or rocks found in tropical climates and which ...

Get Price -

Blast Furnace and Process Description

· Blast Furnace and Process Description: Iron blast furnace is a vertical shaft, which is used to melt the iron ore and to produce hot metal by heat exchange and chemical burden charge consisting of iron oxide, flux and coke and it provides through the throat from the top of the furnace.

Get Price