-

Enhanced Sorption of Cadmium by using Biochar ...

Two sizes of particles have been employed from woodderived biochar which produced by slow pyrolysis at 650°C under Ar gas flow to investigate size and dosage effects of biochar at cadmium (Cd) sorption via batch experiment in a sandy soil. The macro (MBC) ( mm) and nano size (NBC) of biochar divided by sieving and milling by planetary ball mill processes from pristine .

Get Price -

Preparation and Characterization Nanoparticle Calcium ...

Ball milling is one method in synthesis nanoparticle. This method was chosen because it does not require hazardous chemicals in the process. This method has the principle of shrinking particle size by grinding to nanometer size. The ball milling method has been widely used in research, such as milling of porang flour [20], synthesis

Get Price -

ball mills for nanoparticles

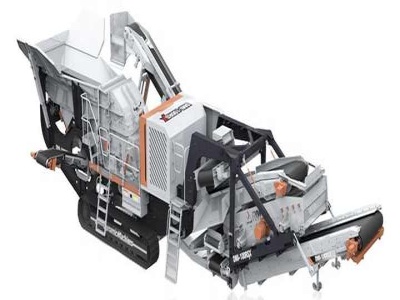

ball mills for nanoparticles; product list. K Series Mobile Crushing Plant; Mobile Vibrating Screen; Belt Conveyer; Sand Washing Machine; S5X Series Vibrating Screen; GF Series Vibrating Feeder; Ball Mill; Raymond Mill; MW Series Micro Powder Mill; T130X Superfine Grinding Mill; MTW Trapezium Mill;

Get Price -

Preparation of magnetite nanoparticles by highenergy ...

Preparation of magnetite nanoparticles by highenergy planetary ball mill and its appliion for ciprofloxacin degradation through heterogeneous Fenton process J Environ Manage . 2018 Apr 1;211:5362. doi: /

Get Price -

ball mills for nanoparticles

ball mills for nanoparticles Beaumont Balades. ball mill for nanoparticles. In our research, we use the highenergy ball milling technique to synthesize various nanometer powders with an average particle size down to several nm, including nanosized aFe 2 O 3 based solid solutions mixed with varied mole percentages of SnO 2, ZrO 2 and TiO 2 separately for ethanol gas sensing appliion

Get Price -

Dispersion Techniques of Nanoparticles

particles [19]. Microwaves, ultrasound, homogenization, media and jet milling have been used to disperse the aggregation [20, 21]. New magnetic field assisted dispersion technique has been applied in industry, including planetary ball milling, ultrasonic and ultraturrax techniques and

Get Price -

Mechanical Milling: a Top Down Approach for the Synthesis ...

· balls and particles in a vibratory mill is complied. The cylindrical container is vibrated and the impact forces acting on the powders are function of the rate of milling, amplitude of vibration, and mass of the milling medium. High energy milling forces can be obtained by using high vibra

Get Price -

HighEnergy Ball Milling

Lei Yang, in NanotechnologyEnhanced Orthopedic Materials, 2015. Highenergy ball milling. Highenergy ball milling is a mechanical deformation process that is frequently used for producing nanocrystalline metals or alloys in powder form. This technique belongs to the comminution or attrition approach introduced in Chapter the highenergy ball milling .

Get Price -

Ball Milling

A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 . Major parameters for ball milling Temperature Size and Number of the balls Nature of the balls Rotation speed 8 . ... Other appliions of ball milling Fine particles

Get Price -

Attritor Mills And Nanoparticles

· Ball Mills an overview ScienceDirect Topics. Ball mills are classified as attritor, horizontal, planetary, high energy, or shaker. ... The major drawbacks of this synthesis method are: (1) discrete nanoparticles in the finest size range cannot be prepared; and (2) contamination of the product by the milling media.

Get Price -

Silicon Nanoparticle Graphite Ball Mill

Silicon Nanoparticle Graphite Ball Mill. Dec 01 2017 highenergy ball mill is employed to convert micrometersized silicon and graphite to nanostructured silicongraphite composite building blocks while a thin carbon coating is applied to encapsulate these composite agglomerates followed by partial etching of silicon to create engineered voids inside the composite agglomerates.

Get Price -

Ball milling: a green mechanochemical approach for ...

Technological and scientific challenges coupled with environmental considerations have attracted a search for robust, green and energyefficient synthesis and processing routes for advanced functional nanomaterials. In this article, we demonstrate a highenergy ball milling technique for largescale synthesis of nitrogen doped carbon nanoparticles, which can be used as an electro .

Get Price -

Silicon Nanoparticle Ensembles for LithiumIon Batteries ...

· colloidal chemistry,10 gas chemistry,11 or through ball milling of larger −14 The latter, due to its low cost, availability, and high throughput yield, represents one of the most common approaches to prepare silicon at the Early research in ball milling of crystalline Si was

Get Price -

A Review of Methods for Synthesis of Al Nanoparticles ...

Highenergy ball milling is a convenient way to produce nanosized powders. It is the most common method reported in the literature for the synthesis of intermetallic nanoparticles. Before a mechanical milling is started, powder (s) is loaded together with several heavy balls (steel or tungsten carbide) in a container.

Get Price -

Grinding Down to the Nanoscale with Planetary Ball Mills

· Planetary ball mills are the most commonly used ball mills in laboratories for preparing samples ranging from soft to hard to brittle and fibrous materials. The mill derives its name from the unique kinematics wherein the grinding bowls are mounted on a rotating "sun" disk that rotate in the opposite direction around the disk centre.

Get Price -

mills for nanoparticles

ball mills for nanoparticles . ball mills for nanoparticles Highenergy ball milling technique for ZnO nanoparticles Apr 29 2011 Nanoparticles of zinc oxide (ZnO) are increasingly recognized for their utility in biological appliions In this study the highenergy ball milling (HEBM) technique was used to produce nanoparticles of ZnO from its microcrystalline powder Four samples were ball .

Get Price