-

Crushing Process Of Ores

150TPH Iron Ore Crushing Plant In South Africa JXSC Mine. JXSC engineer designed the process flowchart of 150TPH iron ore crushing plant for South Africa customers. This stone crusher plant layout on the basis of the iron ore information that customers offered. The information: 050mm materials of the raw ores are %. The density of the perlite ore is 34T/M3, and salt content .

Get Price -

CHAPTER 1 MINERAL DRESSING

So mineral dressing or ore dressing is commonly regarded as processing of raw ores to yield marketable products by such physical means those do not destroy the physical and chemical identity of the ore. Economic Justifiion of Mineral Dressing: 1. To purify and upgrade the ore: It is apparent that many ores minerals do require some prior preparation to enhance their .

Get Price -

Mining of Iron Ores – IspatGuru

· Processing of the ore ranges from simple crushing and screening and separating various size fractions of the ore to the processes that beneficiate or upgrade the quality of the iron ore products. This is done by physical processes, which remove impurities by difference in particle density or size gravity or size separation.

Get Price -

Notes OCCURRENCE AND EXTRACTION OF METALS

Notes 2 CHEMISTRY MODULE 6 Occurrence and Extraction of Metals Chemistry of Elements zlist and explain various methods for concentration of ores (gravity separation, magnetic separation, froth floatation and chemical method); zexplain different metallurgical operations : roasting, calcination and smelting with suitable examples; zchoose the reducing agent for a given ore;

Get Price -

Chapter 2: An introduction to mining

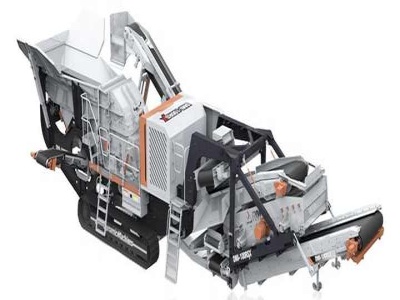

Mineral processing usually requires reducing the particle size of the ore, a process called comminution followed by separating ore and gangue minerals and concentrating ore minerals. The mined ore is tipped into a crusher crushing the blasted rock from the mine to smaller pieces, usually the of small stones or gravel.

Get Price -

Characterisation of the Physical and Metallurgical ...

The blast furnace is still the dominant form of iron production, but over the years, direct reduction methods have increased due to a number of reasons. Overall, iron production methods have optimal requirements with respect to the feed materials especially iron ore. In this study, tests were carried out on Muko iron ore from Uganda to analyse its suitability to meet the feed .

Get Price -

Mineral Comminution and Separation Systems

illustrated in Figure 1 by a simple example. Raw ore, or 'runofmine ore', is received by the storage 1 of the crushing plant for temporary storage, and then discharged through the feeder 2 for controlled rate of supply to the primary crusher 3, where coarse particles included are broken. The broken ore is conveyed to the secondary crusher 5 for further stage of crushing. The secondary ...

Get Price -

Beneficiation of manganese ores with particular reference ...

are beneficiation processes used in the treatment of manganese ores. Careful control of crushing, grinding, and sizing is an essential prerequisite to suc cessful physical concentration. Ores which contain slime forming constituents such as clay, iron .

Get Price -

Rock Crushing methods and How to recover gold from Ores

This iron cylinder is picked up and dropped onto the ore, much in the manner of the old time stamp mills. This method seems to be popular in Australia. A more expensive but certainly faster and easier method is to use a small jaw crusher, such as is used in preparing samples for assaying. I have one of these in my garage and it is pictured at ...

Get Price -

Iron Production

· Iron ore is usually a mixture of iron and vast quantities of impurities such as sand and clay referred to as gangue. The iron found in iron ores are found in the form of iron oxides. As a result of these impurities, iron must be first separated from the gangue and then converted to pure iron. This is accomplished by the method of pyrometallurgy, a high temperature process. The .

Get Price -

Crushing Ores And Smelting

Crushers Iron Ore Smelting Plants In China Iron Ore . Indian iron ore smelting machine price grinding mill equipmentThe production of pig iron from crushing plant Nov 24 2016 India is the only country in the world using Fine iron ore smelting process in cupola furnace iron ore smelting plants indiaPig Iron in India Low Shaft Furnace Smelting ofLow Shaft Furnace Smelting of Pig Iron .

Get Price -

Ore Sintering

· Like other sintering processes, iron ore sintering converts iron ore fines of often − 8 mm sizing into larger agglomerates, namely, sinter, between 5 and 50 mm particle size, which possess the physical and metallurgical characteristics and gas permeability required for efficient blast furnace operation. As shown in Figure, iron ore sintering is carried out in three stages: .

Get Price -

Crushing Process In Cementing

Crushing In Cement Making Process . Crushing the raw materials of cementCrushing of raw material in cement process ement crushing grinding plant in cement production process cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement such as limestone clay iron ore and coal etcimestone is the largest amount.

Get Price -

Innovations: Introduction to Copper: Mining Extraction

The process yields concentrates containing roughly 30% copper, which are sequentially fed to a smelter, a furnace in which most of the some iron and sulfur are removed, then to a converter or converting furnace, where most of the remaining iron and other impurities are removed. (Depending on the type of smelting and converting furnace used, as much as 99+% of the sulfur can be .

Get Price -

How iron is made

Iron ore is converted into various types of iron through several processes. The most common process is the use of a blast furnace to produce pig iron which is about 9294% iron and 35% carbon with smaller amounts of other elements. Pig iron has only limited uses, and most of this iron goes on to a steel mill where it is converted into various steel alloys by further reducing the .

Get Price -

Iron And Steel Production

diagram of the iron and steel industry in Figure Coke production is discussed in detail in Section of this publiion, and more information on the handling and transport of materials is found in Chapter 13. Sinter Production The sintering process converts finesized raw materials, including iron ore, coke breeze,

Get Price -

Experimental study on crushing strength and Young's ...

· Experimental study on crushing strength and Young's modulus of granules in iron ore sintering using Taguchi method. ... The obtained results provide guidelines for sinter production and more basic information on iron ore ... Influence of binder dosage on granule structure and packed bed properties in iron ore sintering process. ...

Get Price -

ASTM E877

E279 Test Method for Determination of Abrasion Resistance of Iron Ore Pellets and Sinter by the Tumbler Test. E389 Test Method for Particle Size or Screen Analysis at No. 4 () Sieve and Coarser for MetalBearing Ores and Related Materials. E882 Guide for Accountability and Quality Control in the Chemical Analysis Laboratory. E1072 Test ...

Get Price -

Chapter 6 Copper Production Technology

Copper ores Copper ore, other minerals, waste (gangue) Copper minerals,b iron and other pyrites, byproducts, andgangue Solution of copper and leaching agent2050 (water orHAO.) Copper, iron (/0), trace amounts of8590 silica and aluminum oxides, and oxygen Organic solvent and pregnantIeachate; 2535

Get Price -

Extraction of Metals (Metallurgy) – Overall Science

· In this method the powdered ore is treated with a suitable reagent that dissolves the ore but not the impurities. The impurities left undissolved are removed by filtration. Leaching method is used for concentrating ores of aluminium, silver, gold,, etc. For example, bauxite ore containing iron oxide as impurity is leached with 45% NaOH solution.

Get Price